The Table below is a variant of the model we have which is SSO 68C give or take If you have only limited space available, but wish to produce your pastry

Model #

SSO 68C

Volts

220

Serial #

C4A081017

Phase

3

Amp

2.9

HP

1

Cycles

60

KW

0.73

Depth

32"

Shipping Weight

500 Lb

Technical Data

SSO 685

Automat

Substructure

A-Frame

Autom. Flour Duster

option

Width of Conv. Belts

25"

Table Length Overall

136 1/2"

Right Table length

63"

Left Table length

67 1/2"

Roller Length

26"

Roller Gap

1/64" - 1 3/4"

Speed of Discharge

Conveyor23 5/8"/sec

Rated Power

1, 5 kVA

Supply Voltage

3x220v 60hz

Req. floor-space in working

position, catch pans extended48" x 154"

Req. floor-space in resting

pos., right hand conv. hinged-up48" x 73"

products more efficiently, the solution is a combined machine for sheeting and cutting. It is the ideal machine for bakeries, but also for restaurants, hotels and food service kitchens. For sheeting, Manomat/Automat-Cutomat is working at the normal sheeting speed. For cutting both belts run much slower and at the same speed, i.e. ideal for cutting and making up the product.

THE ONE-STOP SHOP FOR CHEFS SINCE 1959

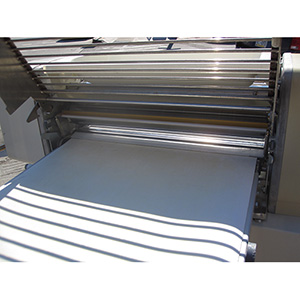

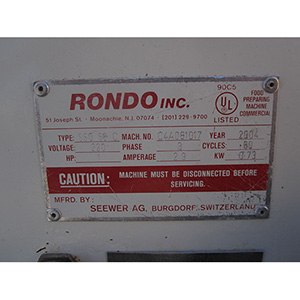

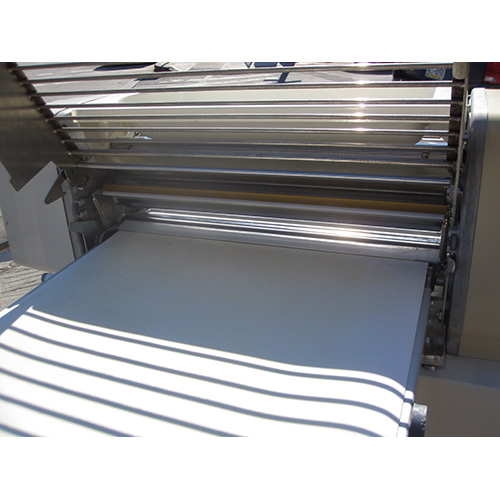

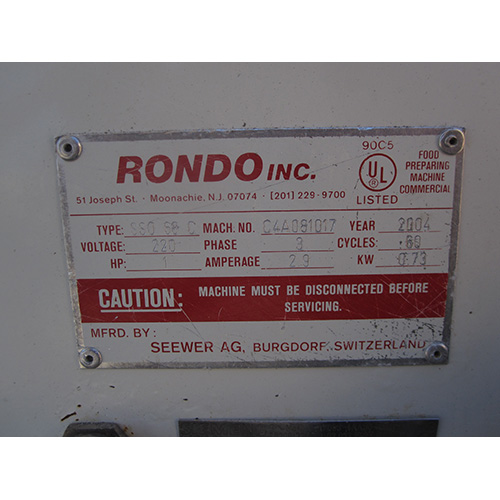

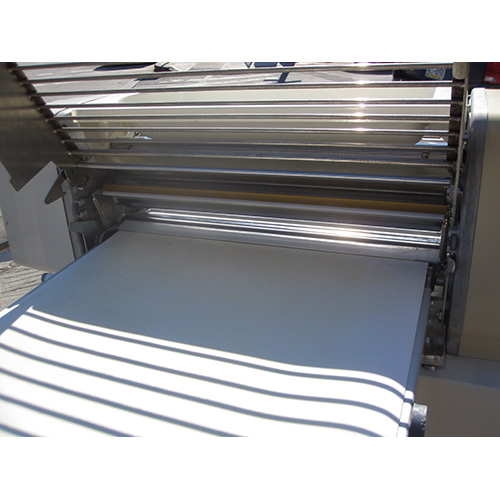

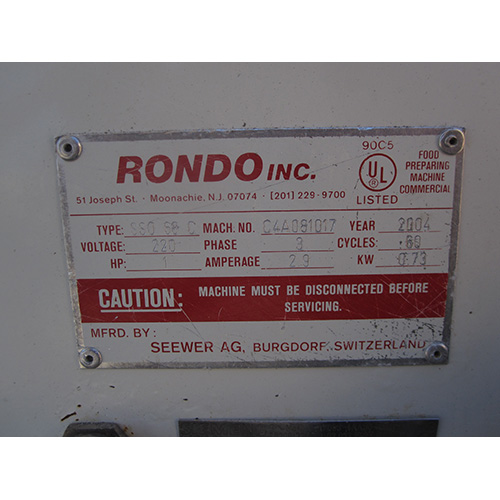

Rondo Sheeter Model # SSO 68C Used Great Condition

Item # USD SSO 68C (4)

Sold

Please contact us at 718-232-7044 if you are interested in this item. We may have similar items available.

Not Qualified for Free Shipping

- Used

- Very Good Condition

- Only 8 Years Old

- Well Maintained

| Model # | SSO 68C | Volts | 220 |

| Serial # | C4A081017 | Phase | 3 |

| Amp | 2.9 | HP | 1 |

| Cycles | 60 | KW | 0.73 |

| Depth | 32" | Shipping Weight | 500 Lb |

The Table below is a variant of the model we have which is SSO 68C give or take

| Technical Data | SSO 685 Automat |

| Substructure | A-Frame |

| Autom. Flour Duster | option |

| Width of Conv. Belts | 25" |

| Table Length Overall | 136 1/2" |

| Right Table length | 63" |

| Left Table length | 67 1/2" |

| Roller Length | 26" |

| Roller Gap | 1/64" - 1 3/4" |

| Speed of Discharge Conveyor |

23 5/8"/sec |

| Rated Power | 1, 5 kVA |

| Supply Voltage | 3x220v 60hz |

| Req. floor-space in working position, catch pans extended |

48" x 154" |

| Req. floor-space in resting pos., right hand conv. hinged-up |

48" x 73" |

If you have only limited space available, but wish to produce your pastry

products more efficiently, the solution is a combined machine for sheeting and cutting. It is the ideal machine for bakeries, but also for restaurants, hotels and food service kitchens. For sheeting, Manomat/Automat-Cutomat is working at the normal sheeting speed. For cutting both belts run much slower and at the same speed, i.e. ideal for cutting and making up the product.

'A' Frame Models

The dough sheeter with maximum flexibility. Theses models with roller openings of 45mm and conveyor widths of 650mm can be supplied with either painted or stainless steel base. When not in use the conveyor can be hinged-up and the whole machine moved. An ideal model for businesses with space problems.

Warehouse Tag # K-2173